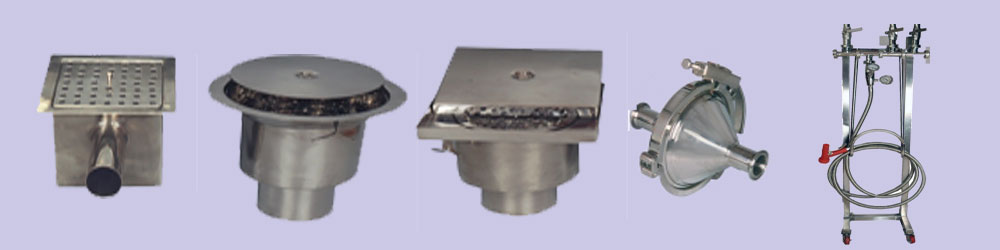

Sanitary Stainless Steel Fittings

The range of sanitary stainless steel bends, tees ,expanders, manifolds, pipe holders, reducers,hose nipples,sight glass and custom designed components are manufactured to tight tolerances of roundness and perpendicularly to facilitate accurate fabrication and orbital welding.The design of fittings has a flush, crevice-free joints, particularly suitable for in-place cleaning.

The range of sanitary stainless steel bends, tees ,expanders, manifolds, pipe holders, reducers,hose nipples,sight glass and custom designed components are manufactured to tight tolerances of roundness and perpendicularly to facilitate accurate fabrication and orbital welding.The design of fittings has a flush, crevice-free joints, particularly suitable for in-place cleaning.

End Connections :

SMS, DIN, TC Clamp, butt-weld; flanged (special design with mating flanges that butt-weld to the tube).

Material of Construction:

SS 304, SS 304L, SS 316 and SS 316L.

Size Range:

1"(25.4 mm), 1 ½"(38.5 mm), 2"(50.8 mm), 2½" (63.5 mm), 3"(76.2mm), 4"(101.6 mm))

View Pdf Catalogue

View Pdf Catalogue

Diaphragm valves are designed to meet 3A standards. The valves are manufactured from SS 316 / SS 316L bar stock/investment castings Diaphragm is food grade EPDM or silicon or viton. End connections can be tri-clamp, flanged or butt weld. The smooth contoured body, pocketless design and electropolished interior surface prevents accumulation of process fluids and contaminants.Can be steam sterilised.

Diaphragm valves are designed to meet 3A standards. The valves are manufactured from SS 316 / SS 316L bar stock/investment castings Diaphragm is food grade EPDM or silicon or viton. End connections can be tri-clamp, flanged or butt weld. The smooth contoured body, pocketless design and electropolished interior surface prevents accumulation of process fluids and contaminants.Can be steam sterilised. GMP Loop Valve can be utilized to eliminate dead legs in the design of point of use outlets in atypical WFI/DM piping distribution loop. As the process fluid flows through the valve body, as demand warrants,the valve isopened providing an uncontaminated sample which may accumulate in outlets greater than 3D. The outlet can also be utilised as a steam condensate drain or as a divert port. The valve has been modified to accept a third port of the same diameter or smaller, positioned adjacent to the bottom of the valve. Typically the GMP valve is oriented in the vertical position. For horizontal process applications, the sterile access valve (T type) is recommended

GMP Loop Valve can be utilized to eliminate dead legs in the design of point of use outlets in atypical WFI/DM piping distribution loop. As the process fluid flows through the valve body, as demand warrants,the valve isopened providing an uncontaminated sample which may accumulate in outlets greater than 3D. The outlet can also be utilised as a steam condensate drain or as a divert port. The valve has been modified to accept a third port of the same diameter or smaller, positioned adjacent to the bottom of the valve. Typically the GMP valve is oriented in the vertical position. For horizontal process applications, the sterile access valve (T type) is recommended Non-return valve is designed to prevent reverse flow with positiveshut off. The valve body is in two parts, assembled by means of a clamping and hygienically sealed with a special seal ring. A guide plate guides the spring loaded valve plug with an O-ring seal. Sizes available are ¾",1", 1 ½", 2", 2½", 3"

Non-return valve is designed to prevent reverse flow with positiveshut off. The valve body is in two parts, assembled by means of a clamping and hygienically sealed with a special seal ring. A guide plate guides the spring loaded valve plug with an O-ring seal. Sizes available are ¾",1", 1 ½", 2", 2½", 3" Butterfly valves are specially designed for powders, viscous media such as gels, toothpaste and creams.Can be welded, screwed, clamped or flange-fitted The valves can be dismantled and assembled without tools and in minutes The valves can can be cleaned and steam sterilised. End Connections can be IDF, SMS, DIN, TC Clamp, butt-weld; flanged

Butterfly valves are specially designed for powders, viscous media such as gels, toothpaste and creams.Can be welded, screwed, clamped or flange-fitted The valves can be dismantled and assembled without tools and in minutes The valves can can be cleaned and steam sterilised. End Connections can be IDF, SMS, DIN, TC Clamp, butt-weld; flanged Sanitary pressure relief valve is spring loaded self setting /self actuating design that is preset and actuated directly by up stream static line pressure. The valve is set at the factory with replacable setting rings that range from 3.5 to 7.5 Kg. The valve can be installed any position, but vertical is recommended to reduce valve wear.

Sanitary pressure relief valve is spring loaded self setting /self actuating design that is preset and actuated directly by up stream static line pressure. The valve is set at the factory with replacable setting rings that range from 3.5 to 7.5 Kg. The valve can be installed any position, but vertical is recommended to reduce valve wear.  The Split Butterfly Valves are designed a to minimize atmospheric contamination during transfers of powders. High containment can be achieved during powder charging, discharging, and sampling . This applies particularly to dust free charging and discharging of laboratory, pilot scale and production process.

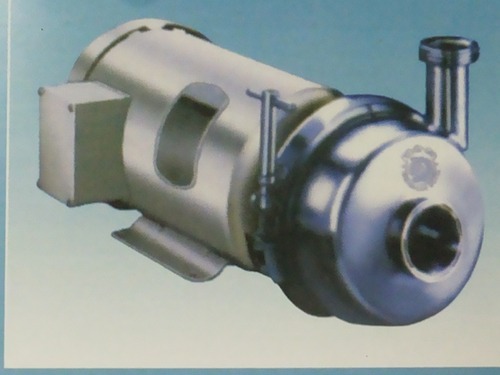

The Split Butterfly Valves are designed a to minimize atmospheric contamination during transfers of powders. High containment can be achieved during powder charging, discharging, and sampling . This applies particularly to dust free charging and discharging of laboratory, pilot scale and production process. TIEWI offer sanitary stainless steel centrifugal pumps for pharma, drugs, food, beverage, dairy, cosmetics and chemical industries. Pumps are monobloc design and manufactured from SS 304 /SS 316 bar stock/sheet metal. All product contact parts(casing, impeller) are in stainless steel, duly electropolished and free from uncleanable pockets.Pumps are fitted with mechanical seals externally mounted. Pumps can be dismantled and assembled in minutes without tools. Pumps can be cleaned and steam sterilised. Drain ports or sampling valves are provided on request.

End connections offered include triclamp, DIN, SMS, flanged and butt-weld Pumps are offered in capacities 3000 litres/hour to 6000 litres/hour

TIEWI offer sanitary stainless steel centrifugal pumps for pharma, drugs, food, beverage, dairy, cosmetics and chemical industries. Pumps are monobloc design and manufactured from SS 304 /SS 316 bar stock/sheet metal. All product contact parts(casing, impeller) are in stainless steel, duly electropolished and free from uncleanable pockets.Pumps are fitted with mechanical seals externally mounted. Pumps can be dismantled and assembled in minutes without tools. Pumps can be cleaned and steam sterilised. Drain ports or sampling valves are provided on request.

End connections offered include triclamp, DIN, SMS, flanged and butt-weld Pumps are offered in capacities 3000 litres/hour to 6000 litres/hour The stainless-steel cartridge housings are designed for final ultra- filtration of liquids or gases through cartridge filters. The housings are designed to ASME code standards, All welds are ground flush, and polished to a high-quality sanitary finish. The housings have a removable cartridge manifold to allow for complete disassembly of the downstream side, and ease of cleaning of all fluid contact surfaces. The housings are in-line steam-sterilisable These housings can accept any cartridge element in various configurations of DOE, code '7', BSP male thread, or tie rod .

The stainless-steel cartridge housings are designed for final ultra- filtration of liquids or gases through cartridge filters. The housings are designed to ASME code standards, All welds are ground flush, and polished to a high-quality sanitary finish. The housings have a removable cartridge manifold to allow for complete disassembly of the downstream side, and ease of cleaning of all fluid contact surfaces. The housings are in-line steam-sterilisable These housings can accept any cartridge element in various configurations of DOE, code '7', BSP male thread, or tie rod . Vent Filter is designed for the sterile air venting of containers and tanks. The housing are made from AISI 316 Stainless Steel, the surfaces are highly polished. Slits in the upper part of the top ensure complete drying out of the system after sterilization ( avoids problems with entrapped moisture ). The housing base has a bayonet-type hold on the upper side and a connector with female threaded nut on the underside

Vent Filter is designed for the sterile air venting of containers and tanks. The housing are made from AISI 316 Stainless Steel, the surfaces are highly polished. Slits in the upper part of the top ensure complete drying out of the system after sterilization ( avoids problems with entrapped moisture ). The housing base has a bayonet-type hold on the upper side and a connector with female threaded nut on the underside  The conical filter separates visible particles from liquids/gases.SS 316/304 quality conical filter comprises of two conical bodies, coupled with tri clamp. The filter element is a stainless steel mesh (100 # to 500 #) supported on a perforated plate and inserted in rubber seat and both being sandwiched for proper seating. Materials - All wetted parts SS316,Gaskets are Silicon, Teflon, EPDM, or Viton

Connection - Tri clamp or DIN or SMS or BSP

Pressure - 10.5 bars max. (150 psig)

The conical filter separates visible particles from liquids/gases.SS 316/304 quality conical filter comprises of two conical bodies, coupled with tri clamp. The filter element is a stainless steel mesh (100 # to 500 #) supported on a perforated plate and inserted in rubber seat and both being sandwiched for proper seating. Materials - All wetted parts SS316,Gaskets are Silicon, Teflon, EPDM, or Viton

Connection - Tri clamp or DIN or SMS or BSP

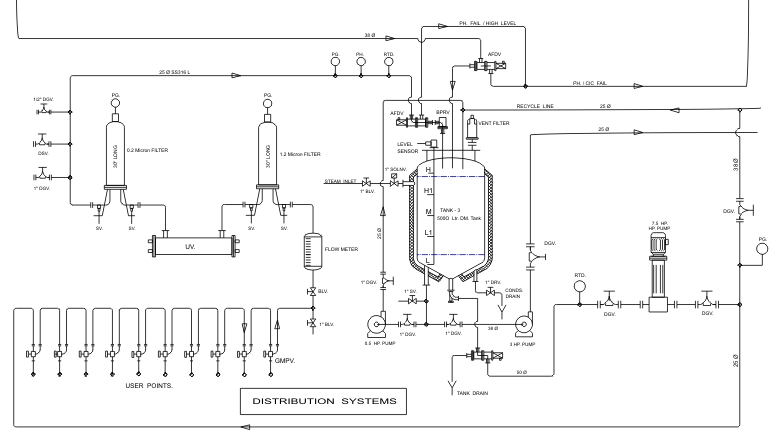

Pressure - 10.5 bars max. (150 psig) IEWI design, manufacture and errect water distribution loops for PW/WFI/Pure Steam generating systems.Our scope of supply includes stainless steel pipes, fittings,valves, storage tanks and related instrumentation.We provide documentation for validation.

IEWI design, manufacture and errect water distribution loops for PW/WFI/Pure Steam generating systems.Our scope of supply includes stainless steel pipes, fittings,valves, storage tanks and related instrumentation.We provide documentation for validation.